source: www.uksoundproofing.co.uk

Various sound solutions have been provided in this website in UK.

Wall Soundproofing

Floor Soundproofing

Ceiling Soundproofing

Wall Soundproofing

几种墙面隔音系统的比较:

Solution 1: Soundstop Panels - Our most popular product due to the ease of installation and quality of results

Soundstop panels are our most popular party wall soundproofing product due to the ease of fitting and quality of the final result achieved.

Materials used in solution 1a:

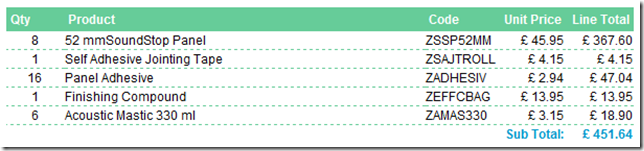

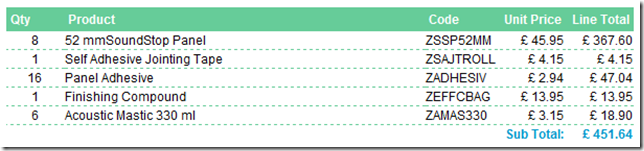

Calculator: Wall Solution 1a: SoundStop Panels 52mm

Materials used in solution 1b:

Calculator: Wall Solution 1b: SoundStop Panels 52mm PLUS 15mm Acoustic Plasterboard

SoundStop noise insulation panels take advantage of advances in acoustic control technology to strike a highly effective balance between increasing the mass of the transmission wall and introducing a dampening air spring element of acoustic mineral wool. The SoundStop panels can be upgraded from providing 13db increased acoustic protection to 16 db increased acoustic protection through the addition of a 15mm layer of SoundBloc plaster board. Fitting Instructions

SoundStop is a uniquely bonded gypsum and acoustic mineral wool product, available in two sizes of thickness, which provide different degrees of soundproofing performance. It has been tested to exacting standards (BS EN ISO 140) and conforms to all UK Health and Safety regulations. The best results for soundstop panels are achieved with solid brick party walls. Breeze block walls may suffer from flanking transmission problems so any soundproofing treatments require an assessment of this possible difficulty (see glossary).

Due to the acoustic nature of stud walls and timber framed walls we would recommend a different set of treatments when upgrading these walls as described in solution 5 stud wall soundproofing.

Example results based on typical party wall construction of 100mm brick wall (45-47db)

So for example after fitting 52mm panels your wall could have a 60 db rating, which is an excellent level of acoustic privacy.

Remember these are average figures across a range of frequencies. In practice all sound proofing works better at higher frequencies.

Our solution is designed to be fitted to just your side of the wall. If you can install to the other side (the neighbours side) of the wall you will experience an even greater acoustic privacy.

Solution 2: Resilient Bars

Materials List (in case of 15sqm application area)

As with all sound insulation projects it is very important to try and introduce a resilience (a springy) layer. In this solution resilient bars are the method of decoupling the wall that you are constructing from the transmission wall i.e. the problem wall. Resilient bars are used in conjunction with acoustic mineral wool slabs and battens. The resilient bars should be attached at 400-600mm centres starting 50mm from the floor. Fitting Instructions

Resilient bars can serve to upgrade an existing stud wall or may be used on brick party walls. In terms of the ideal combination we would suggest the following construction. It should be born in mind that different combinations of materials can be used according to space and budget constraints.

The results achieved by this construction type are excellent. As with soundstop panels acoustic insulation incorporated into floor or ceiling voids maybe necessary. The simplest method of adding acoustic insulation here is to add AMW 60 kg slabs of 100mm completely filling the void beneath floor or ceiling just adjacent to the wall.

Solution 3: Resilient bars with Acoustic membrane

The wall soundproofing described in Solution 2 construction may be further upgraded by incorporating the 1.2mm acoustic membrane, or acoustic quilt between the batten and the resilient bars. The Acoustic membrane is a new, award winning, noise insulation rubber membrane. This membrane incorporates nano vacuum technology, and hence is very light but very effective in attenuating the passage of noise. It can add a further 6+db when added to the construction described in solution 2, which given that sound reduction is measured on an exponential scale is a tangible difference (see glossary for further details). Fitting Instructions

The membrane is ideally added by letting it drape loose affixed to the battens or wall with the resilient bars or battens. This is simply achieved by stapling the acoustic membrane ( or acoustic quilt ) to the top of the stud wall and letting the membrane drape downwards to the floor. The resilient bars are screwed through the acoustic membrane or acoustic quilt in the normal way.

Solution 4: An independent stud wall

If you wish to buy this solution online we can calculate the materials you need. Just click the links below to be taken to the solution calculator:

50mm Stud Wall

50mm Stud Wall with optional acoustic membrane

75mm Stud Wall

75mm Stud Wall with optional acoustic membrane

100mm Stud Wall

100mm Stud Wall with optional acoustic membrane

Where the level of noise from the neighbouring wall is extreme, the erection of an independent stud incorporating acoustic materials will provide the greatest level of wall soundproofing. The stud constructed of metal ( componenets sold on this site or of 75mm * 50mm timber (3 inch by 2 inch), should be erected off the existing wall with a minimum of a 25mm gap. The stud work should not touch the offending wall at any point, and should be affixed to adjacent walls floor and ceiling. The stud work should be in-filled with the appropriate thickness of acoustic mineral wool, i.e. 75mm in this case. The construction on the stud wall follows the same pattern as the the other wall solutions ideally incorporating resilient bars (like Solution 2 and Solution 3) and certainly a double plasterboard layer. With this construction the filling of floor and ceiling voids with acoustic mineral wool (AMW60 100mm) immediately adjacent to the offending wall needs to be considered as this will typically be the weakest acoustic link post construction. In order to keep the wool in place it might be necessary to staple chicken wire or similar meshing to the rear of the stud work.

This construction can further be upgraded with the optional use of an acoustic membrane.

Solution 5 - Soundproofing an exisitng Stud Wall

If you wish to buy this solution online we can calculate the materials you need. Just click the links below to be taken to the solution calculator:

50mm Stud Wall

50mm Stud Wall with optional acoustic membrane

75mm Stud Wall

75mm Stud Wall with optional acoustic membrane

100mm Stud Wall

100mm Stud Wall with optional acoustic membrane

Typically stud walls are built with physical separation of a room in mind. There is little consideration given to the acoustic performance of that wall. In many cases the wall will simply be constructed of 12.5mm plasterboard either side of a 50mm stud frame. To upgrade the wall you will need to remove the original plasterboard from one of the faces of the stud wall.

We offer two solutions that can significantly upgrade a stud wall, the second involving the use of an acoustic membrane. These solutions rely on increasing the mass, the absorbency and the resilience of the separating structure.

Or in plainer English you will increase the absorbency of the wall by adding high density acoustic mineral wool within the existing stud work. The resilience of the wall will be improved by adding resilient bars, these act to separate the new mass that you will be adding in the form of a double layer of acoustic plasterboards.

A further acoustic uplift can be achieved by adding an acoustic membrane to the stud wall between the resilient bars and stud wall. This should add a further 6+db of protection. The acoustic membrane should be hung from the stud work and resilient bars screwed through it as in solution 2.

[End of Wall Soundproofing Section.]

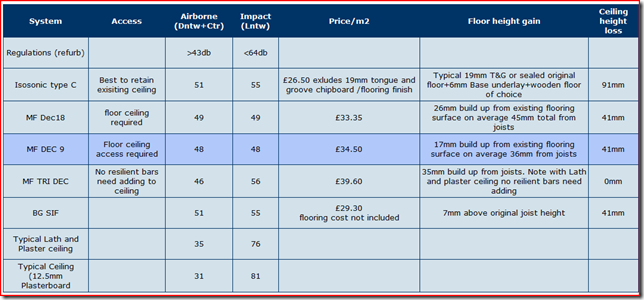

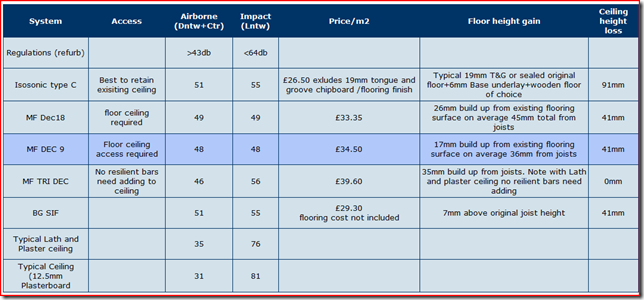

Isosonic Timberfloor

The ISOSONIC TIMBERFLOOR provides safeguards against failure with ‘precompletion testing’.

- Site tested performance far in excess of test requirements

- Simple installation reducing workmanship errors

- Integral flanking sound insulation, eliminating difficult edge strips

- Detailed installation for floor, ceiling, downlighters and partitions- aiding the builder and specifier

SITE TEST PERFORMANCE COMPARABLE TO R.D. STANDARDS

- A high performance, low cost and simple to install system.

- Provides a unique integral barrier to flanking sound transmission which is the predominant cause of test failures.

- ISORUBBER BASE is suitable for the direct application of timber and laminate floors without a board platform.

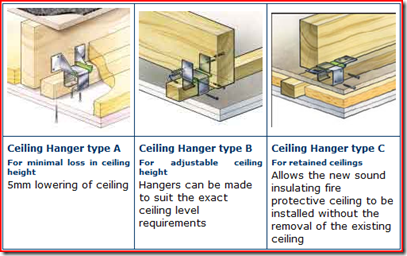

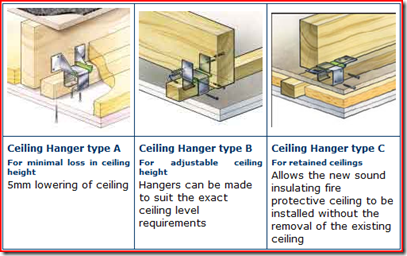

Below shows a detailed set up of isosonic rubber mat and hangers in place. We would recommend keeping the existing ceiling in place if you can.

Other possible hanger options

Isosonic Ceiling Hangers

a) The number of ceiling hangers required per square metre of floor will depend on the geometry of the room. Regular rectangular rooms require approximately 2.5 hangers per square metre of floor area.

b) Spacing of the ceiling hangers should not exceed 800mm.

PACKAGING

Sound Insulation Performance Data

Monarfloor Deck Overlay Systems

Fig. Monarfloor Deck overlay system on a timber sub-floor with a resilient bar ceiling

Fig. Installation of Monarfloor Deck system onto a timber subfloor

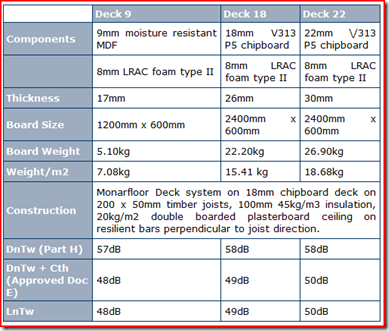

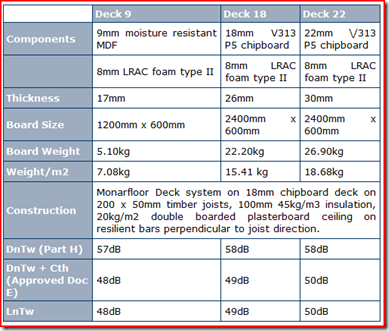

The simplest way of improving the airborne and impact sound performance of an existing timber floor is to overlay the floor with an isolating layer and a new wearing surface. Monarfloor offers three deck overlay systems for such applications:

- Monarfloor Deck 9 - designed for projects where the increase in floor level has to be kept to a minimum. Deck 9 consists of 8mm of LRAC foam bonded to 9mm thick moisture resistant M DF, giving an increase in floor level of only 17mm.

- Monarfloor Deck 18 - designed for domestic timber floors where the existing timber deck remains. Deck 18 consists of a layer of LRAC foam bonded to18mm V313 P5 moisture resistant chipboard.

- Monarfloor Deck 22 - designed for projects where a heavy domestic application is anticipated. Deck 22 consists of a layer of LRAC foam bonded to 22mm V313 P5 moisture resistant chipboard.

Monarfloor Deck overlay systems may be used in new build or refurbishment projects, over 18mm chipboard, OSB board or a decking ply sub floor. Monarfloor Deck overlay systems should be installed directly onto the sub-floor, in broken bond with all joints glued.